ARCOR Farm

We’re guessing you never thought of comparing silage making with a Formula 1 racing team. But pay attention as we take you through the surprising similarities.

The two drivers typically get the credit for success in Formula

- However, without a fantastic car, great engineers, a passionate coach, a strong supporting team, dedicated mechanics, and willing sponsors — the drivers would be hitchhiking!

Two great stories from Argentina right at the silage season peak demonstrate, as with F1, that the driver could do nothing without proper service and support.

Being there for the customer paid off

Fabricio Yannitto, our TSM in Argentina, works with his customers regarding their silage choices, especially when it comes to bunker inspections. With ARCOR Farm, time spent on auditing paid off well, both for the dairy producer and Fabricio.

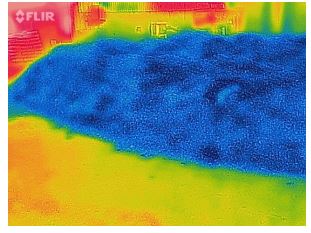

One word – STABILITY – describes in full what is the major talking point in a region, where hot weather during harvest times is a fact. For SILOSOLVE® FC this was no problem! The silage audit showed that silage temperatures – even during this hot time – were close to ambient, and what’s more important: stable. With a pH of 3.7 and, in general, aerobically stable corn silage, all indications pointed in the same direction of a good result! Take a look at the finish line photo below! Infrared photo with cold silage to the right.

The customer was very satisfied with the results obtained using SILOSOLVE® FC. Because of the way they work and manage the silage, SILOSOLVE® FC is a right solution for them, and produced excellent results.

“In the current campaign, we are using SILOSOLVE® FC on all forages, without even a doubt,” claims the farm owner.

So the SILOSOLVE® portfolio has its star driver, as SILOSOLVE® FC is. But this F1 Team has a co-driver, equally skilled and competent, driving fermentation through “hard corners and chicanes” of the difficult-to-ensile alfalfa.

Let us introduce SILOSOLVE® MC and Grupo Chiavassa

The task was simple enough, but we all know that sometimes what may appear simple, unexpected situations can occur.

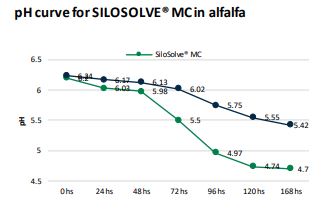

Task: in the pit, take samples of the alfalfa cuts to be ensiled. Compare 6 samples of competitive inoculant with 6 samples of SILOSOLVE® MC. Prepare mini silos. Then open them the

same day. Check it! That task was in the steady hands of Fabricio. Results?

Immediately, you notice the difference: 5.4 for competitive product vs. 4.7 for SILOSOLVE® MC!

SILOSOLVER® MC simply performed!

The obvious difference in the pH values were measured in the first 6 days. A rapid decrease in pH indicated a lower DM loss, in addition to protecting silage quality. If lactic acid bacteria fail to control the fermentation and lower the pH fast enough, there is a potential risk of silage deterioration.

Want to go with alfalfa? Turn to SILOSOLVE® MC!

The keys to have a success story?

Two great drivers: SILOSOLVE® FC and SILOSOLVE® MC – going hard on all tracks and situations. Great tech support, deploying all the tools that allowed the producer to see if the

inoculant worked, a passionate coach, the mastermind TSMwho set the strategy for the “team” with his expertise and hours spent in the field, identifying the pain points of the

producers. That’s what makes a successful team!