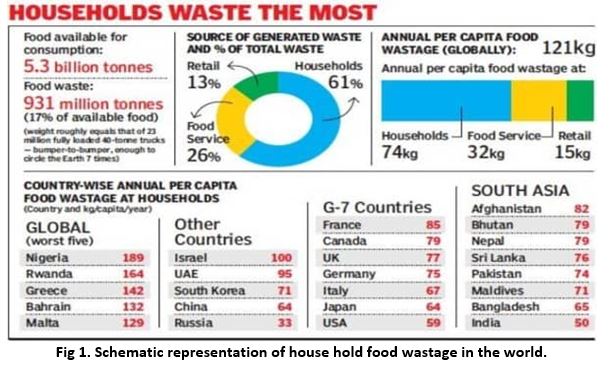

Food waste is a biodegradable waste discharged from various sources including food processing industries, households, and hospitality sector. As per the UN Environment Programme (UNEP) report, UN Food Waste Index Report 2021, globally, the average annual wastage is 121 kg a person. Of this, the share of food wasted in domestic households is 74 kg. China came first with an estimated 91.6 million tonnes of discarded food annually, followed by India’s 68.8 million tonnes. According to this report 50 kg of food is thrown away per person every year in Indian homes. According to the ministry of consumer affairs, food and public distribution, 11,520 tonnes of food grains were wasted in the past four years due to poor maintenance. Among south Asian countries, the highest amount of food is wasted in Afghanistan (82 kg per person per annum) followed by Nepal at 79 kg, Sri Lanka at 76 kg, Pakistan at 74 kg and Bangladesh at 65 kg. India is at the bottom in terms of food wastage.

Proper management and recycling of huge volumes of food waste are required to reduce its environmental burdens and to minimize risks to human health. Utilization of food waste for energy conversion currently represents a challenge due to various reasons. These include its inherent heterogeneously variable compositions, high moisture contents and low calorific value, which constitute an impediment for the development of robust, large scale, and efficient industrial processes. Incineration of food waste consisting high moisture content results in the release of dioxins which may further lead to several environmental problems. Also, incineration reduces the economic value of the substrate as it hinders the recovery of nutrients and valuable chemical compounds from the incinerated substrate. Appropriate methods are required for the management of food waste. Anaerobic digestion can be an alluring option to strengthen world’s energy security by employing food waste to generate biogas while addressing waste management and nutrient recycling.

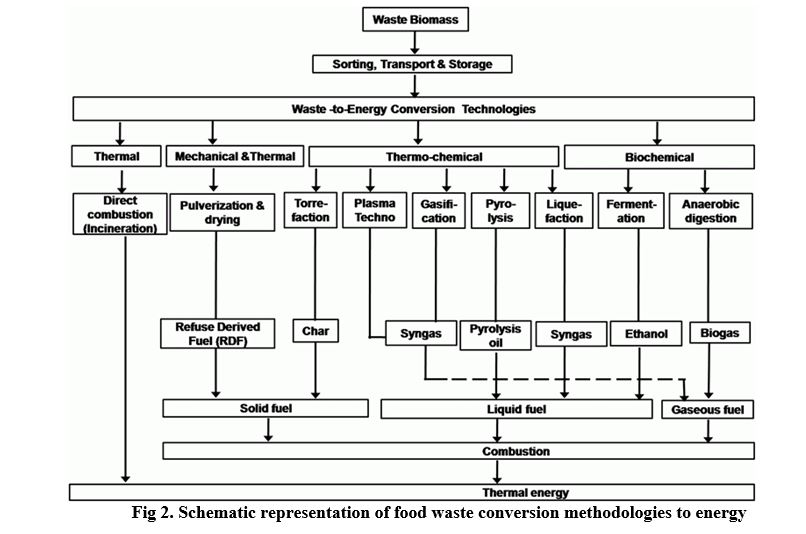

There are various ways to utilise Food waste that are as follows;

- Anaerobic digestion

- Sanitary landfills

- Incineration

- WtE (waste to energy)Technology

- Hydrothermal Carbonisation

- Dendro Liquid Energy

- Anaerobic digestion (AD)

Anaerobic digestion is a biochemical process that takes feedstock and places it in a reactor in the absence of oxygen to create biogas and digest. To do that, reactors are rich in microbial communities that serve to break down the feedstock. It uses more agricultural waste and synthesizes waste that has higher water content through a series of microbial processes to generate biogas. Heat generation can be increased by 90% when syngas/methane is combusted in a cement kiln. Combined heat and power (CHP) WtE plants can have an efficiency of 40% if utilized suitably. The process has lesser cost and low residual waste production and utilization of food waste as renewable source of energy.

- Sanitary Landfills

Sanitary landfills operate by layering waste in a large hole. There are different levels of layering of waste to facilitate the decomposition of the materials as well as trap toxic gases released from the process. The layers are made in a way that the bottom part has the smallest volume, with the top part taking the bigger volume to avoid collapsing of the land.

Incineration is considered when the calorific value of the input feed is at least 7MJ/Kg. When there are no complex collection techniques or when the water content is higher, biochemical methods need to be taken into account. Conversion of thermal energy from incineration can be used to drive a steam turbine for electricity, but only with 15-27% efficiency. Gasification produces syngas that is easily combustible in a gas turbine/engine to generate electricity, which is about 30% efficient.

- Waste to energy (WtE) Technology

WtE technology is an energy recovery process that converts chemicals from waste residues into practical forms of energy like electricity, heat or steam. As of now, thermal conversion techniques lead the market among WtE technologies. MSW (Municipal solid waste) has really low calorific value and directly incinerating it will not generate adequate thermal energy. So, pre-treating MSW into refuse derived fuel (RDF) is more effective.

- Hydrothermal Carbonisation

Hydrothermal Carbonization (HTC) that fast-tracks the slow process of geothermal conversion of wet waste with an acid catalyst at high pressure and heat to simulate the production of ‘hydro-char’ that has properties similar to fossil fuels. The main advantages of this to Anaerobic digestion is the lower processing time and similar operating conditions needed to generate the same amount of energy. It is one of upcoming technologies of world. Hydrothermal Carbonization (HTC) is a thermo chemical process that turns organic waste into structured carbons similar to fossil fuels (that take up to millions of years to form naturally). HTC works with wet feedstock, and the process combines an acid catalyst and pressure at somewhat high temperatures (180 to 250°C) to produce hydro-char, this fossil fuel-like product that has high levels of carbon. Not only can hydro-char be used as fuel but it can also be used to replace coal. The product can also be used to enrich soil, while the feedstock can be used for gasification. The main advantage of HTC over other thermo chemical technologies like pyrolysis is that it doesn’t require pre-treatment (pre-drying) of the feedstock, as it’s designed to work with wet waste, which makes the process a lot faster.

- Dandro Liquid Energy

Dendro liquid energy (DLE) is probably the most promising and upcoming near-zero emissions waste-to-energy technology that treats waste biologically. DLE plants operate at moderate temperatures between 150°C and 250°C, which makes them about four times more efficient in generating electricity when compared to anaerobic digestion and other WtE solutions. Dendro liquid energy plants work with both wet and dry waste to generate clean fuels for electricity like hydrogen and carbon monoxide – basically, it produces syngas. DLE is cost-efficient because the process doesn’t contain combustion, meaning it doesn’t need expensive anti-emission technology to be environmentally safe. japanese porn Some of the main advantages of DLE are that it has a high energy conversion of around 80% efficiency, and near-zero emissions, meaning the byproduct and syngas don’t contain particulates. It is said to be four times more efficient than AD and costs less. It is also one of upcoming technologies.

Regulations for control of food waste

In India, some steps have been taken by the government, civil society organizations and private businesses to reduce wastage of food. The Food Safety and Standards Authority of India (FSSAI) has launched the save food, share food, share joy initiative for the distribution of food that could be potentially wasted. The U.S Food Waste Reduction Act will require food manufacturers and establishments to donate food surplus. Local food waste in U.S may soon dramatically decrease as the House of Representatives approved House Bill No. 8873, or the Food Waste Reduction Act. In Japan target 12.3 calls on all nations to halve food waste and reduce food loss by 2030. To reduce food waste, Japan previously enacted the 2001 Food Recycling Act (Act No. 116 of 2000, amended by Act No. 83 of 2007), which promotes reducing and recycling food wastes into fertilizer and feed. Japan also introduced the “Compulsory Food Waste Reduction Bill, 2018”. The European Commission is taking the issue of tackling food waste very seriously. The EU and the EU countries are committed to meeting the Sustainable Development Goal 12.3 target to halve per capita food waste at the retail and consumer level by 2030, and reduce food losses along the food production and supply chains.

Conclusion:

As the conversion of agricultural land for non-agricultural purpose is growing year on year which may to pose the threat of reduction in the cultivatable land mean to say less production of food grain may cause a serious threat for food security. Reducing the food waste is the best alternative for food security and the proper utilization food waste to energy is an another alternative method to address the energy crisis in the industrial production sector. Europe is said to be the largest market for WtE technologies (47.6%), while Japan dominates 60% of Asia-Pacific WtE market for incineration. However, China has been growing their capacity since 2011. It is said that biological WtE will grow at an average rate of 9.7% as it becomes more commercially feasible. Despite all the advancements, WtE technologies have a long way to go in terms of being on par with conventional energy sources.

Indu Panchal, Sharanagouda B., Sumit Mahaja, and Kartik Alwa