The steady growth of chicken production has led to exponential growth in chicken litter generation. The substances are primarily disposed of in the environment, used as organic fertilizer, or fed to ruminants. Spreading of fresh poultry litter on the land can result in the emission of nitrous oxide, which is a potent greenhouse gas and can affect humans and animals through pathogen contamination.

However, indiscriminate disposal and improper elimination of chicken litter in the surrounding area caused significant environmental and social damage. This growing problem can be ameliorated by converting chicken litter into biofuel via the Biomethanation process.

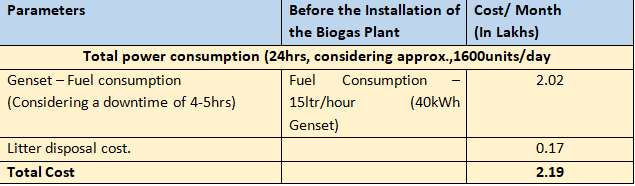

Generally, the birds require an ambient temperature for their best productivity, for which the farm owners need to spend a lot on air blowers and coolers, an exhaustive amount of power is required to run all these equipment, but the power supply is not constant, so they depend on alternative power generation like diesel gensets to keep their equipment’s running. In addition to this, the amount spent on disposing of the litter is huge. An alternative solution to this is Biomethanation, which uses poultry litter as its raw material and generates biogas that can be utilized for power generation at no extra cost. Thus, the handling of litter is managed along with free power generation for the farm.

In addition to the cost above mentioned, maintaining hygiene in the farm adhering to the govt. norms is the greatest challenge as the litter if not disposed off properly, the health of the bird and also the employees are drastically affected.

Biomethanation Process

Biogas is environmentally friendly and one of the most efficient and effective options for renewable energy among various other alternative sources. Biogas is produced by the Biomethanation process, and the effluent from the process is rich in essential nutrients that can be utilized as a very good fertilizer.

Based upon estimates, with the country’s poultry population of 28.6 million and availability of poultry waste of 1,575.5 million kg per year, the biogas yield would be 116.6 million m3/year. This can generate 648 GWh of thermal energy per year. If the thermal energy is converted into electric energy, assuming a 15 percent conversion loss in the conversion of thermal energy to electric energy, approximately 550 GWh of electric energy can be obtained annually.

Different state governments have imposed laws for monitoring the disposal of poultry litter and waste management in the poultry farm as setting up incinerators for the incineration of dead birds.

Koshish Sustainable Solutions, an initiative by a team of professionals from the Indian Institute of Technology (IIT), with more than 10 years of cumulative experience, one of the leading players in Biogas Plant manufacturing, which is majorly working on promoting sustainability, have set up biogas plants across more than 10 states of India,

The technology involved in biogas production is simple and can be implemented cheaply and efficiently by employing small-scale digesters that are easy to use and maintain.

These biodigesters can offer benefits to all spheres of society but are more beneficial to poultry farms. They can use the gas produced for cooking, running biogas generators, and fertilizing crops with the residual waste or sell them.

Biogas plants not only help in processing the litter but also the dead birds can be digested and significantly curb the greenhouse effect: the plants lower methane emissions by capturing this harmful gas and using it as fuel. Biogas generation helps cut reliance on the use of fossil fuels, such as oil and coal, the most important of its many advantages is that biogas can offer a decentralized energy solution.

Economic Viability

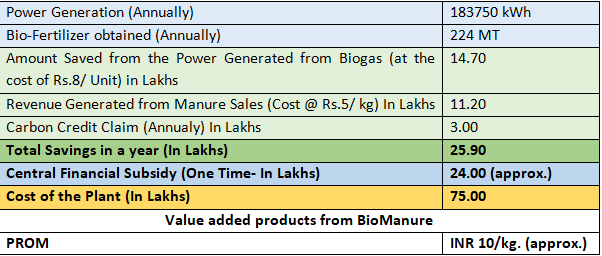

Generally setting up Biogas plants is considered expensive, to promote and support sustainability, Govt. of Inda is supporting by providing subsidies for setting up biogas plants, which may range from 25000 to 5cr, and the payback period of a biogas plant is generally considered to be 3-4yrs. Besides supplying energy and manure, provides an excellent opportunity for mitigation of greenhouse gas emissions and reducing global warming and thereby earning carbon credit, which in turn can be encashed on a yearly basis, thus making biogas plants economically viable.

Waste to Energy

Poultry farms can recover heat and energy from waste. Biogas can run an on-farm electric generator and reduce your electricity costs and the gas generated can be used for heating purposes.

Bio-Fertilizers

Poultry farm digesters are rich in organic nutrients such as N. P and K and will be in dry form which can be packeted and sold as biofertilizers. The revenue generated by the sale of biofertilizers can be on par with the general sale of poultry meat and eggs.

The biofertilizers can be further processed into Phosphate Rich Organic Manure (PROM), as an alternative to DAP and slurry can be also used as a raw material in the manufacturing of biomass pellets (green coal) and green coal can be used in power plants for co-firing. As Ministry of Power (MoP) has also advised coal-based thermal power plants to use a 5-10% blend of biomass pellets

Biogas as CBG

If the biogas produced from poultry waste is considerably high, it can be further purified to CBG, which is equivalent to CNG and can be used in vehicles or filled in cylinders and sold to restaurants and other industries.

A poultry farm with around 50000 birds can be benefitted from the following.

Thus, poultry litter management can be efficiently handled which can help the farm owners benefit economically and fall in line with the different laws imposed by the pollution control board.