Biosecurity in poultry is an integrated strategy that incorporates legal and policy frameworks to assess and control risks related to food safety, animal health, and associated environmental issues. In simple terms, biosecurity refers to the methods for maintaining& keeping infectious diseases away from poultry farms or, if we have a disease issue, how we can prevent our neighbors and farms from contracting it. Millions of farmers in India rely on the poultry industry for their livelihood. The demand for poultry meat and eggs has increased dramatically in recent years, which has led to a surge in this industry’s production. The emergence of birds’ superior strains (broilers achieving the slaughter weight by 35–42 days and layers with longer egg-laying periods) has helped poultry farming evolve to higher production. Antimicrobials are now being used more often and indiscriminately in feed as growth enhancers in the drive for maximizing production. This poses a great risk to the existing AMR crisis.

Good management practices and the application of biosecurity measures maintain the health of the flock and contribute to safer poultry production.

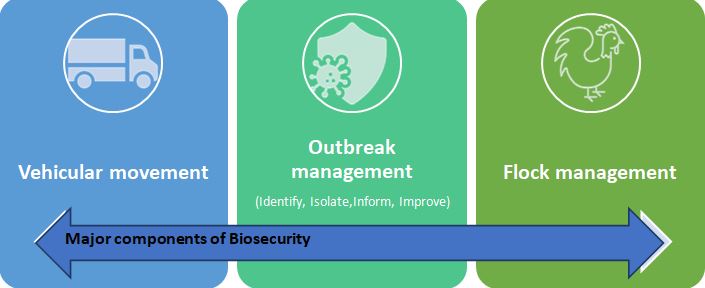

The major component of biosecurity involves,

- Traffic management- Vehicular & human movement

- Outbreak management- Four ‘I’ during the outbreak (Identify, Isolate, Inform, Improve)

- Flock management that involves cleaning & disinfection

Use of sanitizers and disinfectants should be logical and prudent, begin well in advance during flock replacement, and continue until the flock is marketed. Instead of disinfection application only during an outbreak when pathogens have already penetrated through the birds’ system. It is always sensible to practice effective disinfection before any outbreak.

Effective disinfection & sanitization

We must develop our disinfection strategy effectively because the resistance pattern of microbes varies, with microbial spores being the most resistant in nature and enveloped viruses being the most susceptible (CDC, 2008). The effectiveness of various chemicals for disinfection should also be carefully studied. Alcohols and Quaternary Ammonium Compounds (QAC) are categorized as low-level disinfectants, hypochlorite, and iodophors as medium-level disinfectants, and specific aldehydes and peroxygen compounds (oxidizers) as high-level disinfectants. (Hygiene protocols for prevention & control of diseases, Govt of Australia).

Meanwhile, detrimental diseases which occur in poultry due to non-enveloped viruses such as Gumboro’s disease, Chicken infectious anemia, Inclusion body hepatitis & Egg Drop syndrome are associated with resistance to lipophilic agents such as QAC, phenols & biguanides. However certain aldehydes & oxidizers such as oxone (triple salt of potassium) are highly efficient against non-enveloped & other resistant microbes including their spores. (Klein et. al.1995 OIE).

Since not all disinfectants are effective against serious diseases, diverse disinfectant chemistries that alternately target various microorganisms should be taken into consideration as a bottom line.

In poultry, the present trend is to use a triple salt disinfectant complex for efficiently enhancing the redox potential of drinking water resulting in the oxidation of environmental & water-borne microbes that includes even viruses & spores. The use of Oxidation-Reduction Potential (ORP) for “real-time” water monitoring and recording has various benefits. Hand-held devices are affordable and could be the essential backup to cross-verify the operation of an in-line probe.

Studies have revealed that bacteria like E. coli are killed within a few seconds at an ORP value of 600 to 650 mV (Table 1).ORP is thus a more direct measure of water sanitization than free chlorine.

| ORP (mV) | Kill Time |

| 500 | 1 Hour |

| 550 | 100 Seconds |

| 600 | 10 Seconds |

| 650 | 0 Seconds |

Table 1. Amount of contact time needed between an oxidizer & E. coli to kill it based on ORP Values ( Konjoian, 2011)

It is possible to compare different oxidizer products by talking about their oxidation strength in terms of ORP rather than ppm. Instead of evaluating the effectiveness of chlorine dioxide at a particular ppm, chlorine gas at a certain ppm, and peroxide at a specific ppm, ORP permits the comparison of the three treatment modalities on an equal footing. In comparison to chlorine dioxide or chlorine gas, a more peroxide-based product is required to obtain the same ORP. Poultry farmers now have a far better way to gauge a product’s activity based on its ORP than they did in the past by focusing on the product inclusion needed to achieve the desired ppm.

For poultry farm disinfection & water sanitization, a potent triple salt-based non-chlorine oxidant called potassium peroxymonosulphate (or Oxone) is extensively used. The various applications include foot baths and vehicle wheel dips, terminal and continuous farm disinfection, and water quality improvement. Most commercially available non-chlorine oxidizers include 45% potassium monopersulfate, however blended compositions that may additionally include buffers, surfactants, and/or additives for the control of water-borne microorganisms are also available. Potassium monopersulfate needs to be used in conjunction with an EPA-registered sanitizer because it is not a sanitizer. Effective non-chlorine oxidation, or the reaction with organic pollutants that maintains or improves water purity, is the function of monopersulfate. Like comparable chlorine compounds, non-chlorine oxidizers are meant to be used as an additional form of treatment. They offer extra oxidation of contaminants, which lowers the need for the main sanitizer. Since “active oxygen” performs the oxidation process from monopersulfate, it reacts with pollutants without utilizing extra chlorine. (PHTA recreational water committee, 2019)

Oxidising salts such as potassium peroxymonosulphate is an oxidizing disinfectant with quick, broad-spectrum action as it releases chlorine and oxidizes, simultaneously. It is cost-efficient (low rate of use) and can be used on surfaces and in cold fogging. When it comes to steel and rubber (used in boots and tyres), Oxone has been demonstrated to be more successful than quaternary ammonium compounds (QACs), hence it is favoured for foot baths and car wheel dips (Addie 2022).

Traditional oxidising agents have a major limitation, as they have incomplete dissolution in cold water, which causes clogged high-pressure sprayers and limit the base disinfection activity. In contrast, oxidizer-based disinfectants, which dissolved fully in water before use have effective disinfecting properties (Ministry of Agriculture, Govt. of South Korea, Patent publication no.KR102117677B1). Thus, an oxidizing agent that has enhanced solubility & stability should always be preferred to achieve efficient disinfection & sanitization.

As a conclusion, with alternating chemistry to reduce resistance, the use of an oxidizing agent is an effective sanitizing treatment. Strong oxidizer products actively seek for electrons to capture when they are put into the water. Living organisms and other organic substances in water provide a rich source of readily available electrons. To survive and function, bacteria and fungi require a specific electrical balance, and when that balance is upset, it results in detrimental effects such as protein denaturation, cell wall, and membrane rupture, disruption of life-supporting metabolic pathways, etc. In essence, these microbes are killed by oxidation&overall productivity in poultry farms is enhanced.

Dr. Rajib Upadhyaya

Product Manager- Poultry

Cargill India