Introduction:

The term “cold chain” refers to a collection of guidelines and practices that guarantee the methodical synchronization of actions to maintain the proper temperature of items during storage and transportation. Maintaining the integrity and quality of items, such as pharmaceuticals or perishables, from manufacturing to consumption is the aim of a cold chain. An uninterrupted sequence of refrigerated production, storage, and distribution activities, along with related logistics and equipment, is known as an unbroken cold chain. This sequence maintains a desired low-temperature interval to preserve the safety and quality of perishable or sensitive products, like foods and medicines.

The requirement of temperature for storage

Raw meat and meat products should be stored at temperatures that do not pose a health risk since they may encourage the growth of pathogenic germs and/or spoiling bacteria. Throughout the meat distribution chain, the cold chain shouldn’t be broken. Further more, the temperature requirements for different items may vary- Vegetables, for example, require a temperature of 55°F, meat should be preserved at 28°F, dairy goods at 34°F, and ice cream at -10°F.

Microorganisms are killed by extreme heat (cooking, for example), but they are not killed by cold. Because of this, from the time the product is delivered to the consumer until it leaves the slaughterhouse, the cold chain needs to be kept intact. We also need to factor in good hygiene. Both will make it feasible to guarantee food safety and preserve its organoleptic properties.

Importance of cold chain in poultry

In the modern poultry industry, maintaining an efficient cold chain is crucial for preserving the quality and safety of broiler products. The cold chain encompasses the entire process of handling, storing, and transporting perishable goods at controlled temperatures, ensuring they remain fresh and free from contamination. This paper explores the impact of the cold chain on broiler production and discusses effective management strategies to optimize its performance.

Impact of Cold Chain on Broiler Quality:

1. Preservation of Freshness: The cold chain helps to inhibit bacterial growth and enzymatic reactions, extending the shelf life of broiler products and preserving their freshness.

2. Safety Assurance: Proper refrigeration minimizes the risk of pathogenic bacteria such as Salmonella and Campylobacter proliferating in broiler meat, reducing the likelihood of foodborne illnesses.

3. Maintenance of Nutritional Quality: Cold storage prevents nutrient degradation in broiler meat, ensuring that consumers receive products with optimal nutritional value.

4. Marketability: Broiler products that are maintained within the cold chain exhibit better visual appeal, texture, and taste, enhancing their marketability and consumer acceptance.

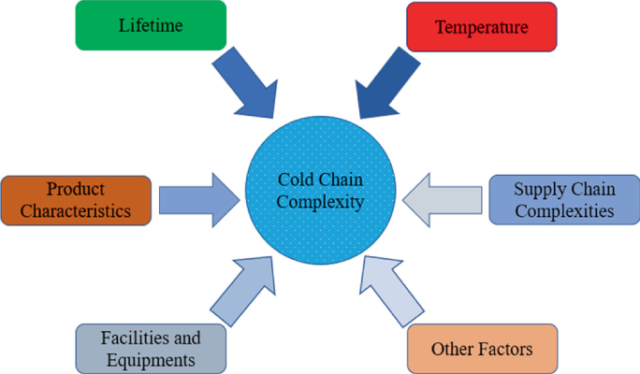

Challenges in Cold Chain Management:

- Temperature Fluctuations: Variations in storage and transportation temperatures can compromise the integrity of the cold chain, leading to product spoilage and quality deterioration.

- Equipment Malfunctions: Mechanical failures in refrigeration units or improper calibration of temperature monitoring devices pose risks to the cold chain, necessitating regular maintenance and quality checks.

- Logistical Issues: Inadequate infrastructure, delays in transit, and improper handling practices contribute to disruptions in the cold chain, affecting the timely delivery of broiler products to markets.

- Cost Considerations: Maintaining a robust cold chain incurs significant operational costs, including energy consumption, maintenance expenses, and investments in refrigeration technology.

- Cross-contamination: contaminating one another takes place on the product’s surface throughout the evisceration, slaughter, and slaughter processes. It happens when hands, clothes, equipment, tools, and other objects come into touch with it.

- Rancidity in meat: Meat provides an ideal environment for microorganisms to break down fatty acids by oxidative changes, which produces peroxides with an off-putting taste and smell.

Management Strategies for Cold Chain Optimization:

1. Temperature Monitoring and Control: Implementing automated monitoring systems and conducting regular temperature checks at critical points along the cold chain ensure compliance with recommended storage conditions.

2. Training and Education: Providing comprehensive training programs for personnel involved in cold chain management enhances their understanding of best practices and fosters adherence to standard operating procedures.

3. Infrastructure Investment: Upgrading cold storage facilities, investing in reliable refrigeration equipment, and establishing backup systems mitigate the risk of cold chain disruptions and maintain product integrity.

4. Collaborative Partnerships: Strengthening partnerships with suppliers, logistics providers, and regulatory agencies fosters transparency and accountability across the cold chain, facilitating effective communication and problem-solving.

5. Quality Assurance Protocols: Implementing robust quality control measures, such as Hazard Analysis and Critical Control Points (HACCP), ensures compliance with food safety standards and enhances consumer confidence in broiler products.

Conclusion:

The cold chain plays a pivotal role in preserving the quality, safety, and marketability of broiler products. By addressing the challenges associated with cold chain management and implementing proactive strategies for optimization, stakeholders in the poultry industry can uphold the integrity of the cold chain and meet the evolving demands of consumers for high-quality, safe food products.

References:

“Cold Chain – PAHO/WHO | Pan American Health Organization”.

“The Vaccine Cold Chain” (PDF). www.who.int. WHO. Retrieved 19 December 2020.

Alavi, S. A., Tabatabaei, S., & Hosseinzadeh, S. (2019). Application of Cold Chain Management in the Poultry Industry. In Postharvest Physiology and Biochemistry of Fruits and Vegetables (pp. 381-395). Academic Press.

Farber, J. M., & Peterkin, P. I. (1991). Listeria monocytogenes, a food-borne pathogen. Microbiological Reviews, 55(3), 476-511.

Jay, J. M., Loessner, M. J., & Golden, D. A. (2005). Modern Food Microbiology (7th ed.). Springer Science & Business Media.

Opara, U. L., & Udeoji, I. N. (2014). Postharvest handling and preservation of fruits and vegetables. In Postharvest Handling (pp. 83-116). Springer, New York, NY.

Raspor, P., Goranovic, D., & Stojceska, V. (2013). Cold chain management in the bakery and dairy industry. In Food Industry (pp. 141-158).

Vinod Kumar Palsaniya and Karishma Choudhary

CVAS, Navania, Vallabhnagar, Udaipur

Email- kumarpalsaniyavinod@gmail.com