MICRO-FLUIDIZATION: A GAME-CHANGER FOR DAIRY PRODUCTS

Micro-fluidization is a cutting-edge technology used in various fields, including pharmaceuticals, dairy products, and food. It helps improve the properties of food, like color, texture, and protein solubility. This technology is particularly effective in controlling microbial growth in dairy and food products by applying high pressure. It’s often used as an alternative to traditional milk homogenization methods, making it a versatile tool in the dairy and food industries. Micro-fluidization is especially useful for producing high-quality products, making it popular in the pharmaceutical and cosmetic industries.

The process involves creating materials with tiny particles, often at the micro and nano scale levels. It’s commonly used to make emulsions, dairy products, and liposomal products in the pharmaceutical and food industries. Micro-fluidizers are devices that use high-pressure pumps to break down fibers by forcing them through narrow channels, creating a high shear rate that tears the fibers apart. The process can be adjusted by changing the pressure, the number of cycles, or the size of the chamber to increase the extent of fibrillation.

One unique application of micro-fluidization is in creating spherical particles that can serve as fat replacements. This is achieved by forcing milk through tiny tubes into an interaction area where high-pressure jets collide, producing very fine particles. These particles have a narrow size distribution and an average diameter of about 0.35 mm, which is smaller than those produced by conventional methods. This technology can also produce fine emulsions and spherically shaped particles that mimic the properties of fat, making them useful as fat alternatives in various products.

Principle:

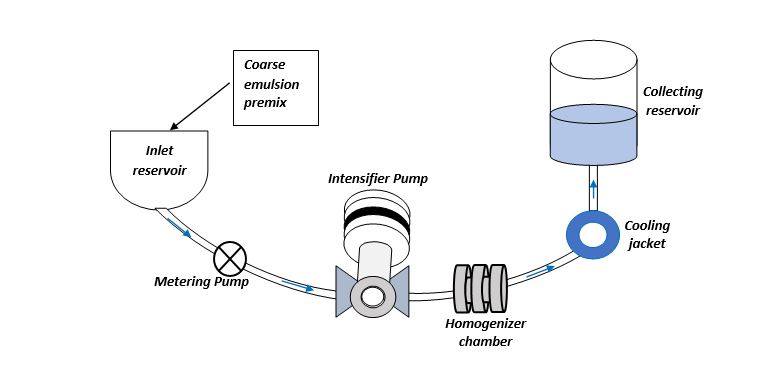

Micro-fluidization uses air-powered intensifier pumps to generate the necessary pressure. The product is pushed through specially designed micro-channels in an interaction chamber, where it experiences extremely high shear rates. This causes the product stream to accelerate to high speeds, leading to uniform particle and droplet size reduction, deagglomeration, and efficient cell disruption.

Working of Microfluidizer:

The sample is first poured into the inlet reservoir.The Interaction Chamber is forced to receive the substance by the Microfluidizer processing continuous pressure pumping system. Operating Pressures of up to 30,000 psi.Fluids inside the Interaction Chamber (a very small micro-Channel) can travel at velocities of up to 500 m/s. All material receives consistent, high-shear rates and impact forces.Then the finished product is cooled and collected.

APPLICATION OF MICROFLUIDIZATION IN DAIRY INDUSTRY:

Encapsulation of Flavours and Additives

Micro-fluidization helps in trapping flavors and additives within tiny capsules, ensuring that aromas are released gradually. This process protects delicate volatile compounds from evaporating or breaking down, extending their shelf life. For example, encapsulating fish oil can mask unpleasant tastes or odors while preserving its stability, making it more palatable.

Extraction of Bioactive Compounds

Micro-fluidization is an efficient and cost-effective method for extracting bioactive compounds. It disrupts the cellular structure of materials, increasing the yield of these valuable compounds. This technology is useful in areas like pathogen detection, controlled yeast growth, and microbial fuel cells. It also has potential applications in bio-refineries and improving microalgae fuel production.

Homogenization of Milk

In milk homogenization, micro-fluidization breaks down large fat globules into smaller ones, resulting in a more uniform distribution. This process can make milk appear whiter and improve the texture and mouth feel of low-fat and non-fat dairy products, such as frozen desserts. It has been effectively used in processing products like infant formulas, cheddar and mozzarella cheeses, and cream liqueurs.

Production of Nanoemulsions

Micro-fluidization can create fine emulsions with tiny particles that mimic fat, making them useful as fat alternatives. This technique extends the shelf life of products like cream liqueurs and infant formulas by producing stable nanoemulsions.

BENEFITS OF MICROFLUIDIZATION IN DAIRY PROCESSING

Microfluidization enhances the texture and sensory qualities of dairy products, leading to improved stability and quality. For example, it can significantly improve the texture and creaminess of low-fat yogurt, making it possible to create premium low-fat versions. It also supports the development of novel cheeses, like low-fat cheeses with desirable textures.

Extending Shelf Life of Dairy Products

Micro-fluidization improves the stability and shelf life of dairy products, such as cream liqueurs and UHT milk, by producing smaller droplet sizes. It also enables the creation of yogurt-like products from hazelnut slurry without additional ingredients. Micro-fluidized cream cheeses have a higher moisture content and softer texture.

Less Energy required

Microfluidizers can create nano-emulsions, such as palm oil-based oil in water, with minimal energy and low surfactant concentrations. This process is efficient and sustainable.

CHALLENGES AND LIMITATIONS

Micro-fluidization has some challenges, such as prolonged emulsification time leading to larger droplet sizes and high-pressure usage raising temperatures. The sensitive micro-channels in the equipment are prone to wear, and over-processing can lead to larger droplet sizes. Additionally, it can disturb the protein matrix, potentially affecting the melt and flow properties of cheese.

CONCLUSION

Micro-fluidization is an innovative technology that improves the shelf life and quality of dairy products. It is used for creating micro- and nano-sized emulsions, encapsulating bioactive substances, and enhancing the functional properties of proteins, polysaccharides, and dietary fibers. The results depend on processing parameters like pressure and the type of substances being processed.

Indu Panchal, Sharanagouda B, Sumit Mahajan and Shiv

College of Dairy Science and Technology, Lala Lajpat Rai University of Veterinary and Animal Sciences