Cold Chain Management in Dairy Industry: Ensuring Quality, Safety and Advancements.

Introduction:

India is the largest milk producer country with total milk production of 239 million tons. In India, Dairy industry is a fast-growing industry with a value of USD 135.30 billion as per 2024 statistic which is expected to grow at a CAGR of 9.33% equivalent to USD 274.09 billion by 2032. Dairy industry provides a livelihood to about 8 crore farmers and also contribute to Indian economy (Indian market size, 2025). Indian government also initiates various schemes for the development of dairy industry such as Dairy federations, Rashtriya Gokul mission, and Dairy Entrepreneurship Development scheme. But the dairy industry faces several challenges including lack of facilities, perishability of dairy products and modernization. Initiatives like government schemes, cold chain management, and development of functional dairy products can overcome these challenges. Cold chain can be defined as a temperature-controlled supply chain ensuring the desired quality and safety of perishable dairy products such as milk, dahi, etc, and shelf life throughout the transportation and storage process (Shukla and Sinha, 2021). This article explores the significance of cold chain management in dairy industry, related techniques, and challenges faced by entrepreneurs.

Importance of Cold Chain in Dairy Industry

Dairy products are highly perishable and susceptible to spoilage caused by bacterial contamination. To overcome these problems, strict temperature controls are required to inhibit the growth of spoilage causing organisms in various dairy products such as milk, butter, and yogurt etc. which leads to increase in shelf life of dairy products. A continuous cold chain is required to keep the product safe, as a small breakdown in supply chain can cause the deterioration of the products. It may lead to financial losses, health risks, and consumer dissatisfaction. According to the study of Mordor Intelligence, India’s market in cold chain logistics is estimated at USD 12.77 billion (2025) which can be projected to USD 20.31 billion by 2030 with a CAGR of 9.72% as forecasted for the period 2025-2030 (Mordor Intelligence report, 2025).

Fig.1 Importance of Cold Chain Technology in Dairy Industry.

Components of Cold Chain Management in the Dairy Industry

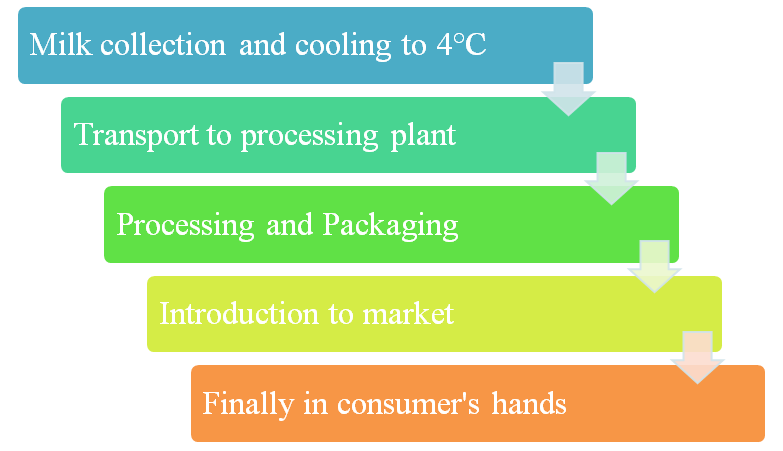

Cold chain management in dairy involves multiple stages which requires a high level of control and attention to detail. The key components include (Shukla and Sinha, 2021):

Milk Collection and Initial Processing

The first step in the dairy cold chain starts at the farm with the cooling of milk to a temperature of 4°C (40°F) or lower after production at the earliest to avoid the microbial growth. At the farm, the milk is typically collected in refrigerated bulk tanks, which maintain the correct temperature until the milk is transported to the processing facility.

Transportation to Processing Plants

Milk is transported to dairy processing plants. During transportation, maintaining the proper temperature is critical. Refrigerated trucks or tankers are used to keep the milk cool during transit. The cold chain must be monitored continuously, and temperature-controlled logistics must be employed to ensure a continuous cold chain management through the way.

Processing and Packaging

At the processing facility, milk undergoes pasteurization or other processing methods to ensure its safety and extend shelf life. Once processed, dairy products are packaged in temperature-controlled environments to prevent contamination. The packaging must also be designed to keep the products cool during transportation and storage.

Distribution to market or Retailers

After packaging, dairy products are distributed to retailers through the same temperature-controlled transport systems. The products are stored in cold storage warehouses and refrigerators until they are sold. During this phase, proper temperature management ensures that the products maintain their freshness and shelf life. At retail outlets, dairy products must be kept in refrigerated displays, and consumers rely on this consistent cold chain to ensure product safety.

Consumer Handling

Finally,it is essential for consumers to store them at the appropriate temperature at home. Dairy products should be refrigerated immediately after purchase and consumed before their expiration date to maintain their quality and safety.

Fig.2. Components of cold chain management.

Challenges in Cold Chain Management

Despite its critical importance, cold chain management in the dairy industry is not without its challenges. The following are some of the most significant problems in dairy businesses (Subin, 2011; Petare, 2013) :

Temperature Fluctuations

Maintaining consistent temperatures throughout the entire supply chain is one of the most significant challenges in cold chain management. Small fluctuations in temperature during transportation or storage can lead to spoilage and bacterial growth.

High Investment Cost

Cold chain facilities require significant investment in specialized infrastructure, such as refrigerated trucks, warehouses, and processing equipment. These systems must be regularly maintained to ensure they function correctly. In developing countries, the lack of reliable cold chain infrastructure further complicates dairy transportation and storage.

Supply Chain Complexity

Dairy products often have a complex and global supply chain. Milk may be collected from multiple farms, processed in one location, and distributed across various regions or countries. Managing the cold chain across different environments, from farms to retail outlets, adds a layer of complexity and increases the risk of cold chain failure.

Regulatory Compliance

Dairy companies must comply with various regulations regarding temperature control. These regulations can differ from one region to another, and companies must stay up-to-date with the latest rules to avoid penalties or product recalls. Keeping track of compliance across multiple markets can be a logistical challenge.

Lack of knowledge and facilities

Traditionally, cold chain management in dairy has been reliant on manual checks and simple temperature recording. However, the lack of real-time data and visibility into the supply chain makes it challenging to detect and address problems proactively. Without proper data, businesses may not be able to identify potential issues until it’s too late.

Technological Innovations in Cold Chain technology

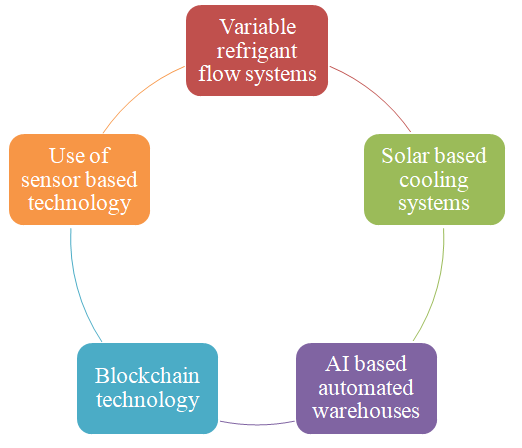

Technological advancements have significantly enhanced cold chain management in the dairy industry. Innovations in refrigeration, sensors, and tracking systems are helping to improve efficiency, reduce waste, and enhance product quality. Some notable advancements include:

Internet of Things (IoT) and Smart Sensors

The Internet of Things (IoT) has revolutionized cold chain logistics in the dairy industry. Smart sensors, connected via the internet, can continuously monitor temperature, humidity, and other conditions in real-time. These sensors send alerts when temperatures deviate from the desired range, allowing for immediate corrective actions. Additionally, data collected from IoT-enabled devices can be used to optimize the cold chain, forecast demand, and improve inventory management.

Blockchain for Transparency

Blockchain technology offers a way to enhance transparency and traceability in the dairy supply chain. By recording every step of the process in an immutable digital ledger, blockchain allows stakeholders to verify the origin and journey of dairy products. This technology improves accountability, helps with regulatory compliance, and reduces the risk of fraud or contamination.

Automated Cold Storage and Distribution Systems

Automation is increasingly being integrated into cold storage and distribution systems. Automated temperature-controlled warehouses use robotics and AI to handle and store products efficiently. In addition, automated cold storage solutions reduce human error, ensuring a consistent cold chain environment.

Advanced Refrigeration Technologies

New refrigeration technologies, such as variable refrigerant flow (VRF) systems and natural refrigerants, provide more energy-efficient and sustainable options for managing cold chains. These systems can help reduce the environmental impact of cold chain logistics and ensure that dairy products are stored at optimal temperatures without waste.

Sustainability and Energy Efficiency

As consumers demand more sustainable practices, dairy companies are investing in greener cold chain solutions. For instance, energy-efficient refrigerated vehicles, solar-powered cooling systems, and eco-friendly packaging are being incorporated into the dairy cold chain to reduce energy consumption and carbon emissions.

Fig.3. Advancements in Cold Chain Management.

Future of Cold Chain Management

The future of cold chain management in the dairy industry is poised for continued innovation. Emerging technologies, such as artificial intelligence (AI), machine learning (ML), and advanced data analytics, are expected to play an increasingly significant role in optimizing cold chain processes. These technologies will improve the accuracy of demand forecasting, enhance supply chain visibility, and enable predictive maintenance for refrigeration equipment.Along with these advancements in technology, few government schemes are also available to meet the investment cost for these latest techniques which include National Programme for Dairy Development (NPDD), National Dairy Plan, Dairy Entrepreneurship Development skills (DEDS), Supporting dairy cooperatives and farmer producer organizations (SDCFPO) and Dairy Infrastructure and Development Fund (DIDF) etc (Naganboyina and Kaple, 2023). As consumer preferences shift toward more sustainable products, the dairy industry will need to prioritize energy-efficient and environmentally friendly cold chain solutions.

Conclusion:

Cold chain management is a critical aspect of the dairy industry, ensuring that dairy products remain safe, fresh, and of high quality. As the dairy industry continues to grow and globalize, effective cold chain logistics will become even more important. By embracing technological innovations and overcoming the challenges of temperature fluctuations, infrastructure limitations, and regulatory compliance, dairy businesses can protect their products, reduce waste, and meet consumer demands for safe and fresh dairy.This article offers a comprehensive analysis of the significance of cold chain management in the dairy industry, the challenges involved, and the future direction of logistics in dairy. By ensuring that cold chain processes are rigorously followed, the dairy industry can continue to meet the demands of an increasingly globalized and health-conscious consumer base.

References:

Naganboyina, T., & Kaple, G. (2022). A Study On Dairy Supply Chain Management In India–Its Development, Policies & Barriers. Journal of Positive School Psychology, 6(8), 1977-1984.

Subin, R. (2011). Country: India’s cold chain industry. The US Commercial Service–Your Global Business Partner.

Petare, P. A. (2013). Issues and challenges of supply chain management with perspective to Indian dairy industry. In Conference vol. of’International Conference on Issues and Challenges in Current Global Economy: It’s Impact on Commerce, Engineering and Technology.

India Dairy Market Size, Share & COVID-19 Impact Analysis, By Type (Milk (Loose Milk andPackaged Milk), Cheese, Butter, Dairy Deserts, Milk Powder, Curd & Yogurt, Cream, and Others) and By Distribution Channel (Supermarkets/Hypermarkets, Specialty Retailers, Online Retail Stores, and Others), 2025-2032. (2025). (FBI107416). F. B. Insights. https://www.fortunebusinessinsights.com/india-dairy-market-107416.

Shukla, I., & Sinha, A. (2021). Cold Chain Supply in Dairy Industry in India. International Journal for Research in Applied Science and Engineering Technology, 9, 2108-2118. https://doi.org/10.22214/ijraset.2021.36671.

Mordor Intelligence report, 2025. Cold Chain Logistics India Market Size & Share Analysis – Growth Trends & Forecasts (2025 – 2030). As accessed on March 26, 2025.

Source: https://www.mordorintelligence.com/industry-reports/india-cold-chain-logistics-market.

Shiv1*, Sharanagouda B2 and Sahil1

1 Research scholar, College of Dairy Science and Technology, Lala Lajpat Rai University of Veterinary and Animal Sciences, Hisar, Haryana, India.

2 Professor and Head, Department of Dairy Technology, College of Dairy Science and Technology, Lala Lajpat Rai University of Veterinary and Animal Sciences, Hisar, Haryana, India.

Corresponding Author mail id: shiv000mangal@gmail.com