Introduction

Appropriate feeding of dairy cattle is of prime importance as feed costs account for more than half of the total costs of milk production. Feed shortage and imbalanced nutrition are major constraints to livestock productivity. Despite these shortages, there is tremendous scope to improve productivity of dairy animals by addressing the issue of imbalanced ratio . A balanced ration must provide adequate quantities of energy, protein, minerals and vitamins from green fodder, dry fodder, concentrates and mineral mixtures. Protein feeds being expensive and scarce, the existing protein resources must be used judiciously. –

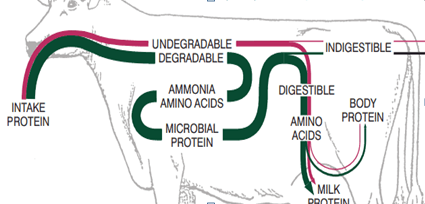

Bypass proteins is an efficient method of improving the protein availability in dairy animal’s diet. These are new generation cattle feed in India and is manufactured by a special chemical treatment, developed by the National Dairy Development Board (NDDB). The ruminant animal has the unique advantage of microbial digestion in the rumen. They supply the major portion of the animal’s protein needs as microbial protein. However, it is inefficient to feed an animal natural protein. The term “bypass protein” shows dietary protein that, either by some means of alteration or because of type of protein is resistant to degradation by the rumen microbes. This undigested dietary protein would “bypass” the rumen and would be potentially available to meet the protein needs of the host animal after digestion in the small intestine.

Protein in ruminant feed

Proteins are biological polymers of amino acids linked together by amide links also called peptide bonds. They contain about 16% nitrogen. The dietary protein for ruminants refers as Crude Protein (CP) which consists of protein component as well as Non-Protein Nitrogen. The CP value is important since protein contributes energy, and provides essential amino acids for rumen microbes as well as the animal itself. Proteins are used for maintenance, growth, reproduction and during milk production in the udder. CP in ruminant diet can be divided into 2 categories based on its degradability during fermentation:

- Degradable intake protein (DIP) – degraded in the rumen to meet the needs of the microbial population. Rumen micro flora breaks the DIP component into amino acids, peptides and ammonia (NH3). This becomes a wasteful process when high quality proteins are broken down to ammonia, excess converted to urea in the liver and excreted through urine.

- Undegradable intake protein (UIP) – proteins that bypasses the rumen to get utilized in small intestine after enzymatic digestion. It is used primarily to meet the extra productive needs of the animalby providing a different balance of essential amino acids for better animal production Characteristics desirable for protected protein supplements is high level of crude protein with optimal essential amino acids profile & approximately 80 per cent of the UIP to be digestible in the small intestine.

Benefits –

National Dairy Development Board (India) has listed the following advantages of feeding bypass protein to ruminants:

- Relatively cheap source of protein for animals

- Availability of essential amino acids is increased

- Improves milk production

- Improves fat and SNF percent

- Improved growth of young animals

- Improvement in reproduction efficiency

- it helps to control Salmonella and reduces mould growth ie. better resistance against diseases.

- Increase the supply of limiting amino acids like lysine and methionine to the small intestine.

- Helps in increasing net daily income

Percentage Bypass estimates of protein sources

| Protein source | % Bypass |

| Blood Meal | 80 |

| Meat Meal | 64 |

| Corn Gluten Meal | 60 |

| Brewer’s Dried Grains | 55 |

| Distiller’s Grains | 54 |

| Dehydrated Alfalfa | 50 |

| Oistiller I s Grains pI us Sol ubles | 49 |

| Soybean Meal | 25 |

Protection of Ruminal Degradable Proteins

Protein and amino acid degradation in the rumen can be decreased by heat treatment (denatures protein with protein –carbohydrates cross links formation that gets protected against microbial attack), chemical treatment with formaldehyde, lignosulfates xylose, tannic acid ,etc , use of amino acid analogues, encapsulation, selective manipulation of balances of rumen metabolic pathways and oesophageal groove closure and use of tannins, and aldehydes. Pelleting, steam rolling or flaking can denature feed protein; therefore protecting protein lysis in the rumen. Starch intrudes with the degradation of protein. It was found that addition of Amylases to cereal grains increased the total ruminal protein degradation.

Results Seen In Production in Dairy Cattles

In tropical conditions, bypass proteins can be fed even to the medium producing animals to increase their productivity. Protein supplement with high bypass value may be considered to increase the milk production of high yielding cows in early lactation when basal diet is poor in nutritive value. Effect of feeding a concentrate mixture containing 37% CP as bypass protein (in experimental group) and concentrate mix containing 50% CP as bypass protein in cows yielding 8-10 litres of milk per day. The animals in experimental group recorded an increase of 1.07 litres of milk per day with a significant increase in fat, SNF and total solids. Whereas the feed costs were reduced, the income of the farmers increased. Higher milk yield in buffaloes fed with formaldehyde treated protein meal. It led to an increase in the yield of 6% Fat Corrected Milk and increase in daily milk production of the order of 1.2 kg per kg of bypass protein in animals fed with bypass protein over those fed with Urea Molasses Block (UMB)).

Conclusion

There remains tremendous scope to improve the production levels of the dairy animals even with the existing resources. It calls for a sustainable use of feeds and fodders and an improved efficiency of nutrient availability. Bypass feed technology has been suggested as one such intervention to improve the efficiency of dairy cattle nutrition.

Shriya Bhatt1*, Manas Arora1, Priyanka Bhandari1, Suyesha Kadam1, Mohit2 Bharadwaj and B.C. Mondal3

1M.V.Sc Scholar, 2PhD Scholar and 3Professor Department of Animal Nutrition, College of Veterinary and Animal Sciences, GBPUAT, Pantnagar, U.S Nagar, Uttarakhand- 263145. Corresponding Author Mail id – bhattshriya@gmail.com

1M.V.Sc Scholar, 2PhD Scholar and 3Professor

Department of Animal Nutrition, College of Veterinary and Animal Sciences, GBPUAT, Pantnagar, U.S Nagar, Uttarakhand- 263145