Introduction

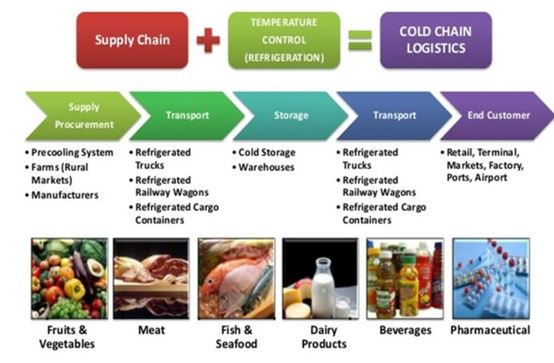

Meat is a perishable product with a short shelf life and therefore short selling times. In contrast to fresh fruit and vegetables, packaged meat has to be declared with a `use by` date. The maintenance of the cold chain is also one of the main principles and basic requirements of European Union (EU) legislation on food hygiene. Raw materials, ingredients, intermediate products, and finished products that are likely to support the growth of pathogenic microorganisms and/or spoilage bacteria, are to be kept at temperatures that do not result in a risk to health. The cold chain should not be interrupted at all times along the meat distribution chain. It is known that shelf life of chilled fresh meat can be extended by various packaging solutions, such as vacuum or modified atmosphere packaging (MAP).

However, a freshness of chilled meat is strongly influenced by temperature. Inadequate storage, distribution, and retail temperatures can lead to a significant reduction in shelf life and early spoilage of meat and meat products. More than 60% of broiler birds produced in India are produced in 6 states(Andhra Pradesh, Telangana Karnataka, Maharashtra, Punjab, and), similarly more than 60% of eggs produced in India are produced in 6 states (Andhra Pradesh, Telangana Haryana, Maharashtra, Punjab, and Tamil Nadu). Birds are currently transported alive between the states, which causes them to be transported in inhumane and sometimes unhygienic conditions. Many birds are killed during transport. Lack of dry processing and cold chain facilities makes it a logistical nightmare to be transporting good quality poultry produce within India. Poultry produce neither are transported using refrigerated trucks nor are specialized equipment used for packing or transporting poultry produce.

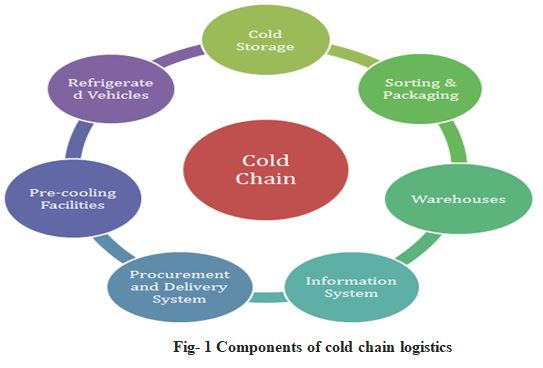

Latest expertise in the field of cold chain can be of immense benefit to the Indian poultry farmer. Therefore, cold chain management in meat supply is of utmost importance for the maintenance of the quality and safety of meat/poultry products. Raw meat/meat products are likely to support the growth of pathogenic microorganisms and /or spoilage bacteria and should be kept at temperatures that do not result in a risk to health. The cold chain should not be interrupted at all times along the meat distribution chain.

The complexity of global meat supply chain, with frequently long distribution chains associated with transportation of the product within one country, from one to another country and from one to another continent, makes the solutions for the chilling and freezing regimes, as well as monitoring of time-temperature profiles, very important for the overall success in delivery of product which will be accepted by consumer for its freshness and safety levels.

Transportation guidelines of Meat & Poultry for cold chain maintenance

During Meat distribution(transportation)route to the final user–wholesale cold storage and/or display at retail, the cold chain must be maintained vigorously. Industrial and/or truck chambers have different characteristics and performances. Its size, initial temperature of incoming meat, targeted temperature during transportation, mechanical characteristics (e.g.power of compressors, ventilation, and insulation),as well as energy /cost matters are issues of first priority when considering the meat distribution/transportation. In general,the vehicle must be provided with a good refrigerated system capable to maintain the required temperature of meat/offal at all times during distribution.

During much of the time from the slaughter of an animal to consumption meat is in transit between distribution points in the marketing channel. It is the responsibility of the transportation industry to deliver meat to areas where demanded. During transportation and storage of meat & poultry, the challenge is to maintain proper refrigeration temperatures. Meat should be transported in a correct manner, to make sure no contamination takes place nor bacteria can grow on the product.

There are three types of meat products produced as a result of slaughter:

- Fresh meat products

- Processed meat products

- Frozen meat products

The transportation of each of these products has different guidelines:

- Frozen meat products for example can be transported all over the world.If a product is processed, the meat is transported from the slaughter house to the meat processing manufacturer and then to retailers and supermarkets.

- Fresh meat products have a limited shelf life and therefore have to be in the supermarket within two days. Fresh meat products are therefore not transported long distances typically. Fresh meat products are transported with trucks from the slaughterhouse to the retailers and the supermarket.

- Processed meat products can either be fresh or frozen. With this being said, trucks are therefore the most common transportation method, especially concerning fresh meats.

- To guarantee a healthy fresh product, the time of transportation from producer to consumer must be as short as possible. Not only time is important to guarantee a fresh product.

The following actions are further taken to ensure food safety during the transportation of fresh meat products:

- Before transportation poultry meat should be and kept at temperatures below 4˚C or 40˚F.

- The meat and meat products should be packaged and checked for leakers, temperature, packaging etc. before transportation.

- Meat is put in packages, boxes or crates when transported.

- Human contact should be limited with the products.

During distribution of fresh meat to wholesale or distribution outlets, temperature may increase abruptly with little opportunity to re-cool. Temperatures within the container sometimes vary 15 to 20 degrees. Transportation Equipment, although probably capable of maintaining a cool environment, must be opened and closed frequently for deliveries. Training of personnel responsible for distribution of fresh meat to wholesale or to retail outlets is vital if temperature increases are to be kept to a minimum.

Mr. Manoj Kumar Singh (Asst.Prof.)

Department of Livestock Production Management,COVAS, SVPUAT, Meerut, Uttar Pradesh