Recent years have been marked by below-average rainfall and above-average temperatures in several parts of the world. In the US, the drought of 2012 was the worst in more than 50 years. Southern Europe, Russia, China and Ukraine have also suffered from higher temperatures and lack of rain. These conditions have necessitated changes to normal annual harvest and forage management practices.

Drought-stressed corn can be a good source of high-quality silage, but the key is to manage it carefully — from harvest to packing, and from storage to feed out.

Here is a quick guide to ensuring high feed values from drought-stressed corn silage:

Closely monitor whole-plant moisture

The whole plant moisture of drought-stressed corn still standing in the field can be deceptive. Even if it looks dry and dead, it can contain over 70% moisture. Start testing moisture levels two to three weeks prior to anticipated harvest. Ideal dry matter at chopping should be between 30% and 38%, depending on the type of storage. Once the plant dies, it can dry down quickly, so be prepared to harvest fast. When dry matter exceeds 38%, using a silage inoculant, such as SiloSolve® FC or SiloSolve® AS, can help minimize problems during feedout.

Be aware of varying levels of crop stress, moisture and nutrient content

Different soil types and conditions create variable crop stress, moisture and nutrient content within a field, so you want to continuously test for moisture during harvesting. During feedout, increase nutritional testing so you can make adjustments for variability and reduce the risk of feedout problems. We recommend SiloSolve® FC to accelerate fermentation over a broad range of moisture levels and improve aerobic stability during feedout, especially if you are short of forage and expect to start feedout well before three months of fermentation.

Pack, pack and pack again

Drought-stressed corn silage packs like grass or cereal silage. To increase the packing density, additional weight on the packing tractor may be needed. Consider using Biomax® Pro to quickly lower the pH level and decrease residual plant cell respiration caused by the presence of oxygen.

Test nitrate levels

Drought-stressed corn is often high in nitrates. Nitrates tend to accumulate in the lower stalk, so cutting at 12 to 15 inches can decrease

nitrates in the silage. However, this might not be practical because it will reduce your tonnage. Note that nitrates levels can spike after rain, so it’s best to wait three to five days after rain before you start harvesting the crop. Silage fermentation can reduce nitrate levels by 20 to 50%, but allow at least four weeks after ensiling for nitrate levels to fall before feeding. Test silage for nitrates prior to feeding and periodically during feeding to assure nitrate levels are below detrimental levels. For extra assurance, Biomax® Pro promotes rapid fermentation, which helps convert nitrates to a safe form.

Be aware of dangerous silo gas

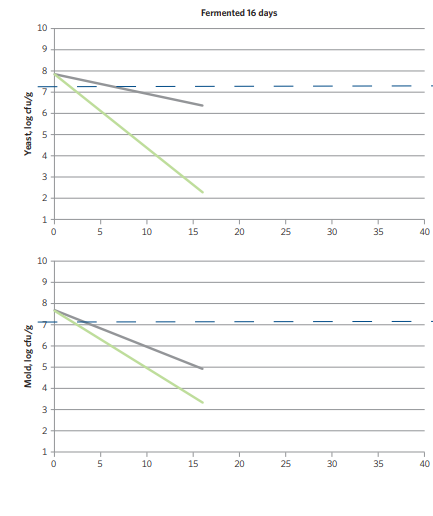

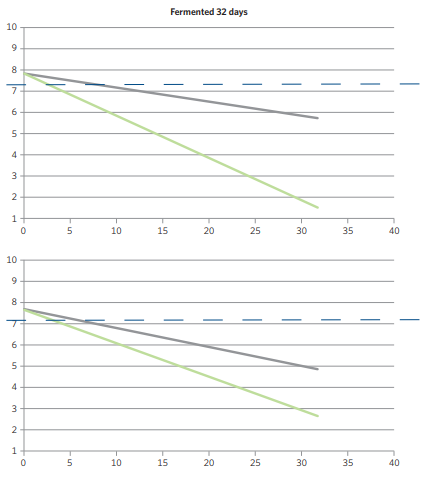

Silo gas is always a concern with corn silage and increases with higher nitrate levels in drought-stressed corn. Nitrates can turn into nitrous dioxide, an extremely toxic gas. Even brief exposure to silo gas may cause permanent injury or death. Proceed with extreme caution if you notice a faint, brown-tinted, low hanging gas, stained forage or a bleach-like odor. If you detect any of these signs, leave the area immediately. Look for signs of mycotoxin contamination from the field Drought-stressed corn is particularly vulnerable to mold- and/or yeast-spore invasion. This typically takes place when corn pollinates under drought stress and high heat. To inhibit the further growth of molds and yeasts in the silage, consider applying SiloSolve® MC.

Monitor closely, even if crop conditions improve

Severe drought stress causing abnormal plant and ear development requires careful management, even if more normal rainfall returns later in the season. Mycotoxin threats may actually increase. Expect the crop to have lower starch, higher but more digestible fiber, and elevated plant sugars. Biomax® Pro and SiloSolve® MC efficiently use soluble sugars to rapidly drive fermentation to low terminal pH —ideally < 4.0 — helping you get the most feeding value from every ton of silage harvested.

Don’t underestimate the value of drought-stressed corn

Although grain content may be low or not present, drought-stressed corn silage can have up to 75% to 90% the nutritional value of normal corn silage. Ask your nutritionist for advice on feeding drought-stressed corn silage.

Early feed out – an additional challenge

In addition to the challenges of managing drought-stressed corn silage, if you are short on forage, inadequate fermentation time and aerobic stability of the new crop at feedout may compound the issue. SiloSolve® FC hastens fermentation and extends aerobic stability in as few as two to four days after sealing the silo, although we recommend a minimum of seven days of fermentation.

By: Kristian Witt,

Global Product Manager, Silage