India is ranked 1st in milk production contributing 23 per cent of global milk production. Milking the animal is an art that requires skill and experience. Milking is an important operation in the dairy farm which directly affect the income. An ideal milking method is one which ensures proper labour utilization and helps in reducing the cost of milk without any detriment to udder and health. Cows are generally milked from the left side. Milking should be completed within 5 to 7 minutes.

2022 Yamamoto Nutrition Pro Bodybuilding Results and Recap buy testogel online dostinex : dostinex 0.5 mg 8 tablet kullananlar, dostinex que hace, dostinex side effects bodybuildingMilking Preparation

- Tie the cow to stanchion.

- Washed the milking barn after each milking.

- Brush and wash the hind quarter thigh and udder.

- Udder region of the cow should be dried with a clean towel.

- Tie the legs along with the tail with a tight slip knot.

- Wipe the udder and teats with the towel soaked in antiseptic solution.

- Milker should wear a clean dress and cover their head with suitable caps.

- Milker nails should be trimmed and hands should be cleaned and disinfected.

- Milker should be free from infectious diseases.

- Massage the udder for a let-down of milk.

- Draw off few streams of fore milk from each teat in the strip cup and observe abnormality, if any.

- Hold the diagonal teats and milk in a full-hand method of milking.

- First few streams of the milk should not be mixed with the rest of the milk as the former contains the highest number of bacteria.

- Milk the cow quickly, silently and completely with dry hands.

Methods of Milking

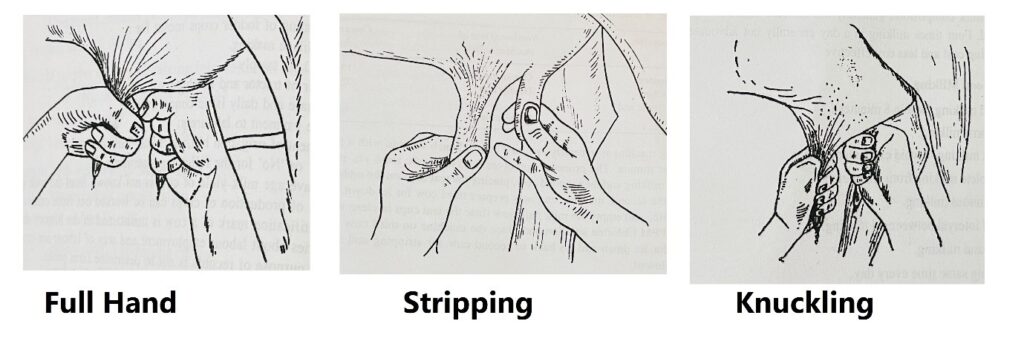

Full Hand – This is the best method of milking. In this the teat is closed at the base between the thumb and index finger in this manner, and the milk that has become trapped in the teat sinus is pushed out by pressing with the other finger on the teat. This method is superior to the stripping as it stimulates the natural suckling process by calf.

Stripping – Cows having small teats are milked using the “stripping” method, which involves strongly pushing down on the teat’s base with the thumb and index finger while extending them along the whole length of the teat to force milk out in a stream. It causes more injury and irritation to teats.

Knuckling- This is a bad method of milking. In this method, the thumb is bent against the teat. It should always be avoided to prevent injuries of the teat tissues.

Machine Milking- It works on the principle of vacuum to extract milk from the teat. Machine milking is commonly used in herds having high-yielding and large numbers of cows. On a dairy farm, the milking process is one of the labor-intensive tasks. More and more dairy farms are converting to machine milking as a result of the rising demand for milk. Maintaining udder health and milk quality as well as achieving milking performance depends on the milking machine’s proper operation. The Machine milking unit consists of a pulsator system, vacuum supply system, and milk flow system. The suspension cup, teat-cup assembly, and connecting air and milk tubes are all part of the milking apparatus that is connected to the udder. The teat cup is made comprised of a steel outer shell and an inflation-style liner that fits over the teats.

As the pulsator functions, the inflation squeezes and relaxes on the teat, causing the milk to flow into the system. The duration of the milking and resting phases of the pulsation cycle is known as the pulsation ratio. The number of pulsations per minute is referred to as the pulsation ratio. Typically, the pulsation ratio ranges from 1:1 to 2.5:1. After cleansing the udder, apply the milking machine gently between 30 to 60 seconds. As soon as the milk flow ceases, remove the milking machine immediately by first releasing the vacuum. Dip the teat ends in an antiseptic solution to clean them. Teat cups and milk utensils are quickly rinsed with warm water.

Traditionally, the majority of dairy farmers relied on labourers or electric milking machines to collect milk from the cows or buffaloes on their dairy farms. Now by utilizing Green technology by using renewable energy milking equipment powered by solar energy, which lowers their power expenditures and labour costs can also be used.

Conclusion

Milking operation is the major activity of every dairy farm affecting the quantity, quality and cost of the milk produced. India is still hand milked, as the majority of farmers cannot afford the costly electrical milking machine. Machine milking saves time, labour cost, increase the milk yield and ensures clean milk production and welfare of an animal.

Authors:

Anuj Kumar1*, D K Singh2, Amit Kumar3, Ahmad Fahim4

1Ph.D. Research Scholar, Department of Livestock Production Management, SVP University of Agriculture and Technology, Meerut, 250 110, India

2Professor, Department of Livestock Production Management, SVP University of Agriculture and Technology, Meerut, 250 110, India

3Professor and Head, Department of Livestock Production Management, SVP University of Agriculture and Technology, Meerut, 250 110, India

4Assistant Professor, Department of Livestock Production Management, SVP University of Agriculture and Technology, Meerut, 250 110, India

Corresponding author: Email- *drvetanuj@gmail.com