Introduction

The dairy industry in India works largely on procurement play. With an average of two cows each, dairy farmers have been the sole suppliers of milk to larger cooperatives and milk brands. In fact, most of the large brands we see are only processors and not producers of milk themselves. With businesses now setting up their own large-scale farms and owning cattle to become producers, the industry as a whole is going through major changes. By adopting the role of both supplier and producers, they are gaining an edge as they have complete control over the milk production, quality, and efficiency. Since these boutique farms already have the cattle and the capital, the only thing required to make it a profitable business is the implementation of technology. It is amply clear that the demand already exists. There are certain aspects of farm management which if handled through technology can reduce costs and make operations efficient. A few of them are:

The Health of the Cattle

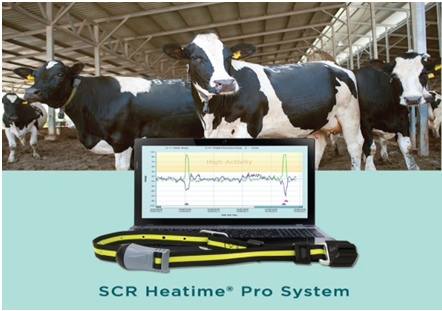

Getting a high yield from cattle depends entirely on their health. While tracking the health of a larger number of cattle at a farm can get tough, there are trackers in the market that work the way smart watches work. These trackers monitor the heart rate and other vital signs of the cow and analyzes its health. Some of these can also track the heat period, and other aspects, just by analyzing their movement patterns. An overview of such health reports is available with the vets who help in quick response and action.

Anomalies in Milk Production

Near Field Communication, Radio Frequency Identification (RFID), and Bluetooth Low Energy (BLE) are technologies that have been in use for a long time to track the health of cows. Systems today provide animals with a unique identification number that helps track the animal’s production and understand their health patterns. Using these existing technologies, hardware installed at farms, such as milking parlors, are able to ID the cow or buffalo. Once identified, its milk production is then matched with standard patterns and production history in order to understand and identify anomalies. Identification of such anomalies can help dairies reduce losses and increase production efficiency.

Field to Yield Impact

Fodder plays a very important role in milk production, as it has a direct impact on the quality and taste of milk. The feed constitutes the major cost of a dairy’s operation. Hence, it is very important that the feed is of the best quality, to ensure a greater yield in terms of both quantity and quality. Milk processors in India pay the producers based on the fat level – higher the fat content, the higher the payout. These different aspects of the feed and the yield have to be documented by the dairy farms in order to get the required information and a better understanding of the feed to yield impact. This is possible only via a collective effort by the dairies, which can happen over a period of time when more and more dairy farms become digitized. It is something that we can hope to see in the near future.

Product Lifecycle Tracking

Since the margins for milk processors are higher in the case of value-added products, tracking the lifecycle of milk, to the market and the quantity that comes back – within expiry range – can make a big difference. Milk that gets returned from the market while still within the expiry range can further be converted to products like ghee, paneer, buttermilk, curd, etc. which reduces the losses significantly and also adds to the margin. Enabling tracking of the product lifecycle, like tracking the retailers who are carrying products which are about to reach expiry and collecting them in a timely manner, through an alert system can make great difference.

Last Mile Delivery

Since the milk producers and processors both play the scale game with low margins, saving costs on every front and increasing efficiency are very important factors. Last-mile delivery includes dropping off milk either to the retailer or to the household (in case of B2C). Both B2B and B2C deliveries require management of cold chain to avoid spoilt products and also to maintain quality. Tracking of logistics and route optimization along with temperature reporting are some simple options to do the same. In many cases, the pouches develop leaks, while the bottles and the crates used get damaged, leading to losses. These losses are not entirely avoidable, but understanding the root cause or identifying the problem areas can help in corrective measures being taken. The first step to solving a problem is recognizing that there is one.

TECH INNOVATIONS FOR DAIRY OPERATION

Gone are the days of low-tech livestock operations. From parlor monitoring systems to detection of hidden mastitis in your herd, companies are introducing technology that improves not only herd health but also your bottom line.

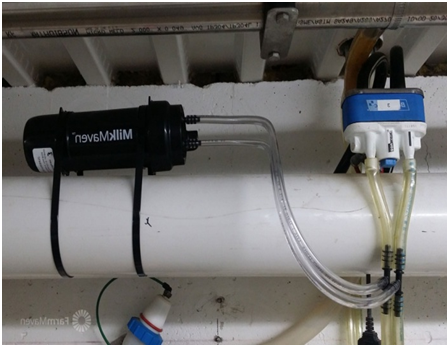

MILKMAVEN

Combining advanced hardware and software, Milk Maven uses sensors to continuously check pulsator health, milk, wash, glycol temperature and the vacuum pump. If Milk Maven detects any issues, a notification is sent to a computer or mobile device with a web browser, offering suggestions on the possible source of the problem. The cloud-based application, which is a division of Farm Maven, also lets you perform diagnostics of the milking phase ratios with the click of a button.

Cost is dependent upon size of parlor.

RT10 SSC

- With the RT10 SCC and iPhone app, you can easily identify high SCC or subclinical mastitis cows and make better decisions to lower your overall SCC. This SCC readings can be determined in seconds – without the expense and time of sending samples off to the lab.

- The device not only provides a cow’s SCC but also indicates the type of bacteria most likely to have caused the high SCC, which can help in determining proper treatment.

This tool allows you to export data into a spreadsheet or email a file to share with trusted advisers.

QSCOUT FARM LAB

- Undetectable to the naked eye, sub-clinical mastitis is often missed. Yet, it diminishes milk production and threatens herd health. Annually, mastitis costs the U.S. dairy industry $2 billion, or about $200 per cow.

- It’s time to challenge mastitis with a new breed of on-farm diagnostics: QScout Farm Lab. This portable diagnostic analyzer identifies and differentiates leukocytes (white blood cells) in milk. Each of the three blood cell types – macrophage, neutrophil, and lymphocyte – plays a role in fighting infection and each has a different function.

- Understanding their roles and ratios allows for more accurate detection of subclinical mastitis.

Sachin Dongare1, S. K. Singh2, Chaitali Dongare3, Mohit Bharadwaj4, Sumit Gangwar5 and Manoj Kumar Singh6

1,5 Ph.D. Scholar, Department of Livestock Production Management, Govind Ballabh Pant University of Agriculture and Technology, Pantnagar, Uttarakhand

2Professor, Department of Livestock Production Management, Govind Ballabh Pant University of Agriculture and Technology, Pantnagar, Uttarakhand

3Assistant Professor, Department of Animal Husbandry and Dairy Science, Lokmangal Agriculture College, Wadala, M. P. K. V. Rahuri, M.H

4 Ph.D. Scholar, Department of Animal Nutrition, Govind Ballabh Pant University of Agriculture and Technology, Pantnagar,Uttarakhand

6Assistant Professor, Department of Livestock Production management, SVPUA&T,Meerut, U.P

Corresponding Author Email id- sachindongare12345@gmail.com