Introduction

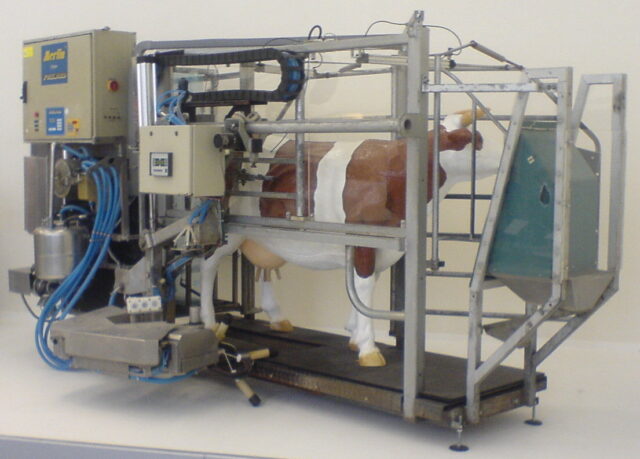

Automatic milking/robotic milking is the milking of dairy animals, especially of dairy cattle, without human labor. Automatic milking systems (AMS), also called voluntary milking systems (VMS), were developed in the late 20th century. They can also be used to monitor the health status of cows. The milking process is the collection of tasks specifically devoted to extracting milk from an animal. This process may be broken down into several sub-tasks: collecting animals before milking, routing animals into the parlor, inspection, and cleaning of teats, attachment of milking equipment to teats, and often massaging the back of the udder to relieve any held back to milk, extraction of milk, removal of milking equipment, routing of animals out of the parlour.

Technical Aspects

Voluntary milking allows the cow to decide her own milking time and interval, rather than being milked as part of a group at set milking times. AMS requires complete automation of the milking process as the cow may elect to be milked at any time during a 24-hour period. Typical capacity for an AMS is 50–70 cows per milking unit. AMS usually achieves milking frequencies between 2 and 3 times per day, so a single milking unit handling 60 cows and milking each cow 3 times per day has a capacity of 7.5 cows per hour.

An AM system has six main modules:

1. Milking stall

2. Teat-cleaning system

3. Teat detection system

4. Robotic arm device for attaching the teat cups

5. Control system including sensors and software

6. Milking machine

1.The Milking Stall

AM systems can be divided into one and multi-stall systems. The one-stall systems have a milking stall with an integrated milking machine and a robot device for attaching the teat cups. The multi-stall systems have up to five stalls and a mobile robot device, which moves from one stall to another to attach the teat cups. All AM systems are equipped with an electronic ID reading systems to identify the cow’s ID tag in order to decide if the cow has to be milked or not. AM systems have a concentrate dispenser to make the cow’s visit to the system more attractive.

2.Teat Cleaning System

The purpose of cleaning the teats is primarily to remove dirt and other particles that can contaminate the milk. Automatic cleaning is also necessary to meet international legislation and hygiene rules from the dairy industry. Automatic cleaning devices also stimulate the milk letdown process.

3.Teat Detection System

The udder shape and teat position will differ substantially from cow to cow and besides breed and genetic merit are dependent on milk production, milking interval, deformation of the udder shape due to cows lying in the cubicle, and stage of lactation. Moreover, cows, although they are locked up, can move in the milking stall and so the position of the teats will change. AM systems have active teat detection systems to localize the four teats.

4.Robotic Arm

Different types of robot arms are used. Some robot arms imitate conventional milking by using an arm with a gripper, which picks up the teat cup from a storage rack at the side of the stall. The four teat cups are attached in succession.

5.Control System and Sensors

AM systems need sensors to observe and to control the milking process as the milker is doing. These sensors are the ‘eyes’ of the AM system and their task is to monitor the technical functioning of the AM system, like cow identification, teat cup attachment, vacuum level, and the start of the milk letdown process. The control unit in fact acts as the ‘brains’ of the AM system.

6.The Milking Machine

The milking machine is more or less similar to the milking systems in conventional milking parlors, except for the cluster. AM systems lack a milking cluster and are based on individual quarter milking.

Advantages of Robotic Milking

a. Elimination of labour.

b. The milking process is consistent for every cow and every visit and is not influenced by different persons milking the cows.

c. Milking frequency may increase to three times per day, however typically 2.5 times per day is achieved.

d. There is a perception that elective milking schedules reduce cow stress.

e. The use of computer control allows greater scope for data collection and record keeping.

f. Better herd management.

Disadvantages of Robotic Milking

a. Higher initial cost

b. Increased electricity cost.

c. Touchscreen display of a milking robot and increased complexity.

d. Possible increase in stress for some cows due to unknown reasons.

Conclusion

Robotic milking is an advanced and automotive system which eliminates several human errors and works more efficiently with accuracy and precision. Hence to improve herd health and milking practices in modern dairy farms it may prove to be a better option in the future dairy technology.

Also, read | Microbes in Fermented Dairy Products

Authors:

Shivali Khandelwal*1 and Vishal Yadav2

1 M.V.Sc. Scholar, Department of Veterinary Microbiology and Biotechnology

2 M.V.Sc. Scholar, Department of Veterinary Gynaecology and Obstetrics

College of Veterinary and Animal Science, Bikaner

Rajasthan University of Veterinary and Animal Sciences, Bikaner (RAJUVAS – Bikaner), Rajasthan – 334001, India

*Corresponding author: Shivali Khandelwal (M.V.Sc. Scholar), email:

shivalikhandelwal11@gmail.com