A commonly asked question about silage management is, “What are the differences between using a bacterial silage inoculant versus a direct acidification product such as organic acids, like propionic acid?” This question is most easily addressed once we establish a foundational understanding of the similarities and differences between the two types of products.

Bacterial silage inoculants have been investigated since the early 1900’s. The very first silage inoculants were often not viable due to limitations in the microbial technology at the time. The theory behind the use of silage inoculants was that by adding live, viable bacteria we could drive fermentation toward a desirable endpoint. The original theory still holds true today.

This is accomplished by using specifically-selected bacteria that outcompete the epiphytic bacteria in terms of replication and production of fermentation acids. This efficiency provides for a rapid fermentation which helps reduce energy losses associated with fermentation and dry matter loss.

Lactobacillus plantarum was the dominant silage inoculant species until about 40 years ago when the use of additional species of bacteria was introduced. The different species provided unique characteristics such as production of large amounts of lactic acid early in the fermentation process, or the ability to continue producing lactic acid at lower pH levels. In the mid-1990’s research began on Lactobacillus buchneri, which is heterofermentative, meaning it can produce more than one product during fermentation.

Simply stated, in addition to producing lactic acid, it produces acetic acid which helps limit yeast and mold growth and thereby enhances aerobic stability of the silage.

Fairly recently Lactococcus lactis O-224 has been included in SILOSOLVE® FC to replace some of the more-established strains. This strain has some very unique properties as it is a superior oxygen scavenger that has enabled early opening of silos in as few as 7 days. Without question, bacterial silage inoculants are generally regarded as safe (GRAS), easy to handle and non-corrosive to equipment.

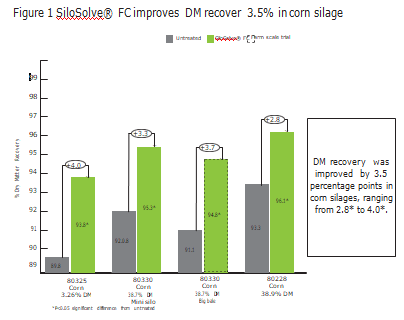

When reviewing some of the classical data from Bolsen et al. (1992), we see improved DM recovery by 1.3 percentage points, 1.8% more efficient gains and 3.6 lbs. more gain per ton of crop ensiled when a single strain silage inoculant was compared to an untreated control. More recent research has shown improvements of more than 3.5% in DM recovery (Figure 1). A few studies have reported improved efficiency of energy-corrected milk production through the use of science-based, research-proven bacterial inoculants.

The research that has been conducted on bacterial silage inoculants by Chr. Hansen and others overwhelmingly has shown the value of using bacterial silage inoculants. By comparison, research is somewhat lacking for organic acid products. Silage review articles give little thought to the use of this technology. While it can work if used correctly based on moisture, crop type and stage of maturity, it is more cumbersome than inoculants which are proven effective and can be applied at the same rate for all crops.

Organic acid products such as propionic acid are direct acidifiers as they decrease the pH of the silage mass directly. This is simply due to adding an acid to the silage mass. Historically, larger amounts were used that resulted in a restricted fermentation. The addition of organic acids can inhibit yeast and mold through antimycotic activity. This simply means that yeast and molds typically do not survive in the presence of organic acids; thereby increasing aerobic stability.

The application rate of acids tends to be variable and is dependent on the moisture of the crop ensiled. Likewise, crops with higher buffering capacity, such as alfalfa, require higher rates of application. If propionic acid is applied in its base form it can be very corrosive to equipment. As salts of acids have become more readily available, this has become less of a concern. Research using these products is fairly limited and is only applicable to similar crops at similar moistures.

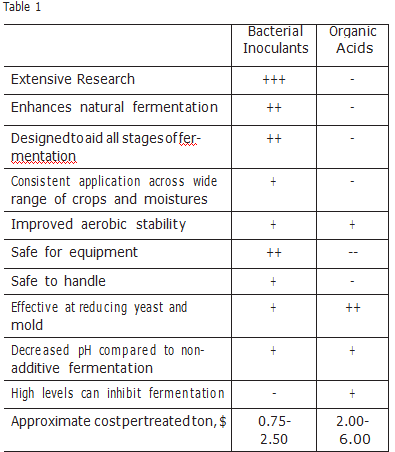

A comparison of the favorable and unfavorable attributes of bacterial silage inoculants compared to organic acids is shown in Table 1.

Silage technology has progressed significantly in the last 40 years, evolving from single species (not strain) bacterial inoculants to modern multi-strain inoculants where each strain is selected for a specific purpose. These modern products outcompete the native microflora and facilitate the achievement of ideal fermentation endpoints.

While organic acids have had a significant value to silage making in the past, this technology is not able to progress as it is based on acidifying the silage mass, not fermentation. Bacterial inoculants have been proven to improve DM recovery, and enhance aerobic stability, both of which are financially important to operations feeding ensiled feeds.

Inoculants are extensively studied both during development and after a product is introduced. This continued research furthers the understanding of the silage making process and helps determine what future improvements can be made. This is important for both producers and the livestock they feed as further improvements in silage fermentation can have an impact on animal performance, feed quantity and quality, and the bottom line of the operation. A science- based, research-proven bacterial silage inoculant provides all of the features and benefits of organic acids along with several additional advantages.

Dr. Keith A. Bryan, Technical Service Specialist